Stone masonry is a time-honored construction technique, celebrated for its durability and aesthetic appeal. However, like all forms of construction, it comes with its own set of risks and hazards. Ensuring safety on a stone masonry site is crucial for protecting workers, maintaining productivity, and achieving high-quality results. Here’s a comprehensive guide to putting safety first in stone masonry.

Pre-Construction Planning

Before the first stone is laid, a robust safety plan should be in place. This includes:

Site Assessment: Conduct a thorough inspection of the construction site to identify potential hazards such as unstable ground, nearby overhead power lines, and confined spaces.

Safety Training: Ensure all workers receive comprehensive training in stone masonry techniques and safety procedures. This should include proper lifting techniques, the use of personal protective equipment (PPE), and emergency response protocols.

Tool and Equipment Checks: Verify that all tools and machinery are in good working order and suitable for the tasks at hand. Regular maintenance schedules should be established to avoid malfunctions.

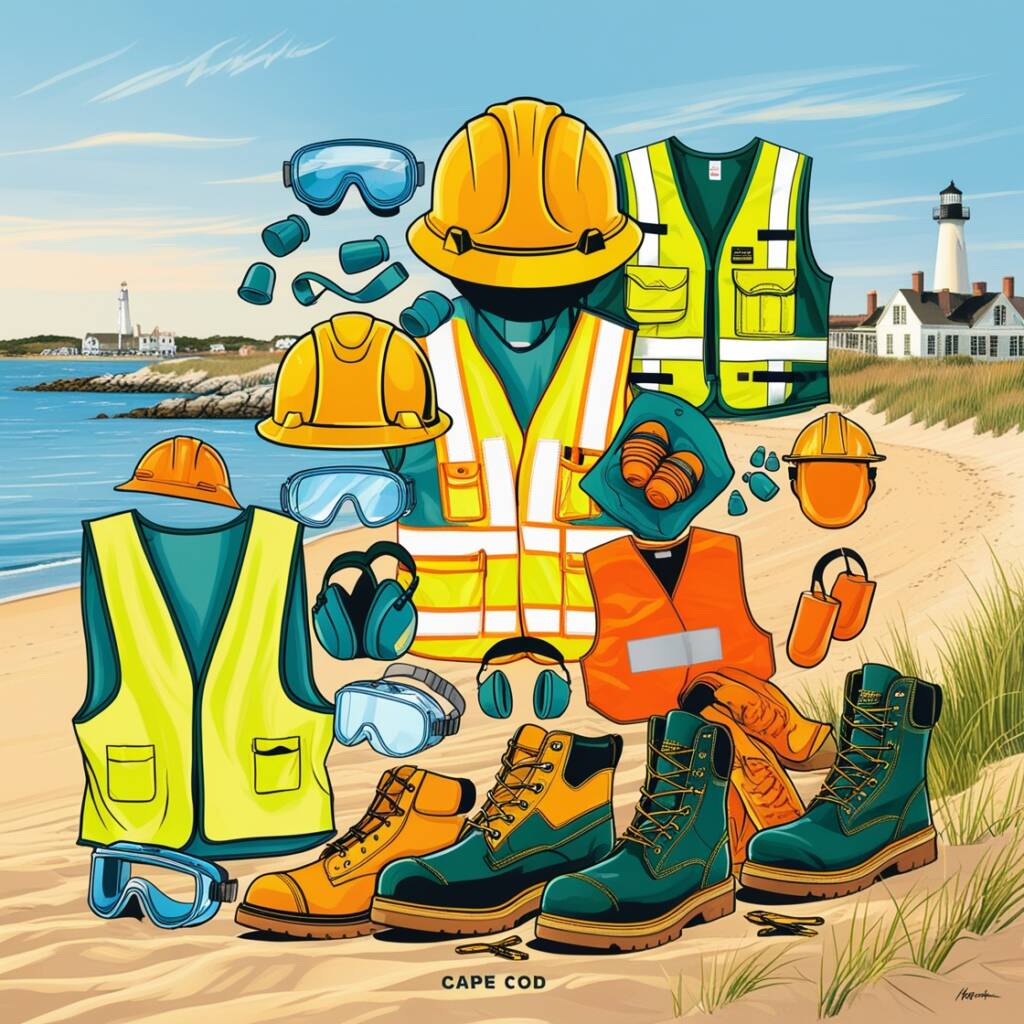

Personal Protective Equipment (PPE)

PPE is essential for safeguarding workers against the physical demands of stone masonry. Key items include:

Hard Hats: Protect against falling objects and head injuries.

Safety Glasses: Shield eyes from dust, debris, and splinters.

Gloves: Provide grip and protect hands from cuts and abrasions.

Steel-Toe Boots: Guard feet from heavy stones and equipment.

Hearing Protection: Use earplugs or earmuffs to protect against noise from machinery.

Respirators: For tasks that generate significant dust, respirators can help prevent respiratory issues.

Safety Glasses: Shield eyes from dust, debris, and splinters.

. Safe Handling of Materials

Stone masonry involves handling heavy and sometimes unwieldy materials. To ensure safety:

Proper Lifting Techniques: Train workers in correct lifting techniques to avoid back injuries. Use equipment such as cranes or hoists to lift heavy stones whenever possible.

Material Storage: Store stones and other materials in a stable, organized manner to prevent them from falling or causing tripping hazards.

Clear Pathways: Maintain clear and unobstructed pathways around the site to allow for safe movement and quick evacuation if necessary.

. Use of Tools and Equipment

Tools and equipment must be used correctly to prevent accidents:

Inspection and Maintenance: Regularly inspect tools and equipment for wear and tear. Ensure they are properly maintained and repaired as needed.

Correct Usage: Train workers in the correct use of tools such as chisels, trowels, and masonry saws. For machinery like forklifts and cranes, ensure operators are certified and experienced.

Tool Safety: Use tools according to the manufacturer’s instructions and wear appropriate PPE when operating power tools.

Worksite Safety Protocols

Creating a safe work environment involves more than just using the right equipment and PPE:

- Signage: Clearly mark hazardous areas with warning signs and barriers. Ensure that all safety signs are visible and understood by all workers.

- Communication: Maintain open lines of communication among all team members. Use radios or other devices for instant communication, especially on larger sites.

- Emergency Procedures: Establish and practice emergency procedures, including evacuation plans, first aid, and emergency contact numbers. Ensure all workers are familiar with these procedures.

Weather Considerations

Weather conditions can significantly impact safety on a masonry site:

- Weather Monitoring: Keep an eye on weather forecasts to anticipate changes that could affect safety, such as high winds, rain, or extreme heat.

- Adjusting Work Practices: Modify work practices based on weather conditions. For example, avoid working at height during high winds and take breaks during extreme heat to prevent heat stress.

Regular Safety Audits and Feedback

Continual improvement in safety practices is vital:

- Safety Audits: Conduct regular safety audits to identify and address potential hazards. This helps ensure that safety protocols are being followed and are effective.

- Worker Feedback: Encourage workers to provide feedback on safety practices and report any hazards or near-misses. This feedback can provide valuable insights into improving safety procedures.

Safety in stone masonry is a multifaceted endeavor requiring proactive planning, the proper use of PPE, correct handling and use of materials and equipment, and adherence to worksite safety protocols. By prioritizing safety and fostering a culture of vigilance and preparedness, construction sites can protect their workers, ensure efficient operations, and produce high-quality masonry work. Remember, a commitment to safety not only saves lives but also contributes to the long-term success and reputation of any construction project.